Ecobunker Advanced

Second generation synthetic golf bunkers from the world’s first.

EcoBunker Advanced is the strongest and most efficient method of constructing stacked sod walls using synthetic grass tiles. The method was designed and developed exclusively by Richard Allen.

Whilst the original was good, EcoBunker Advanced is better. Why?

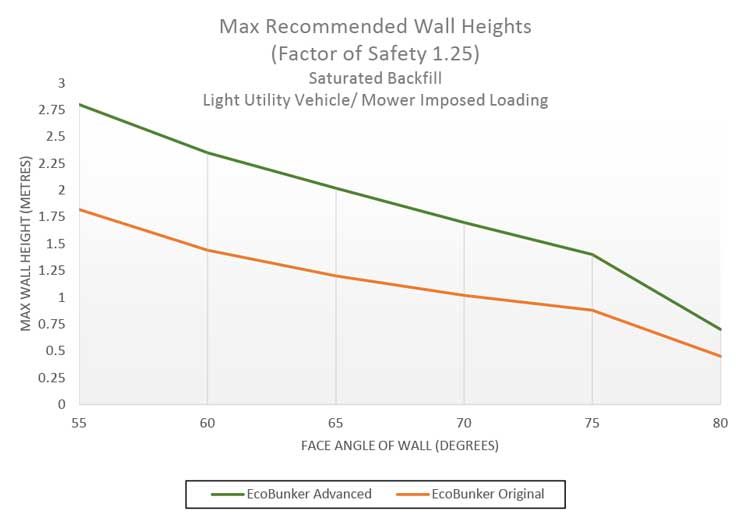

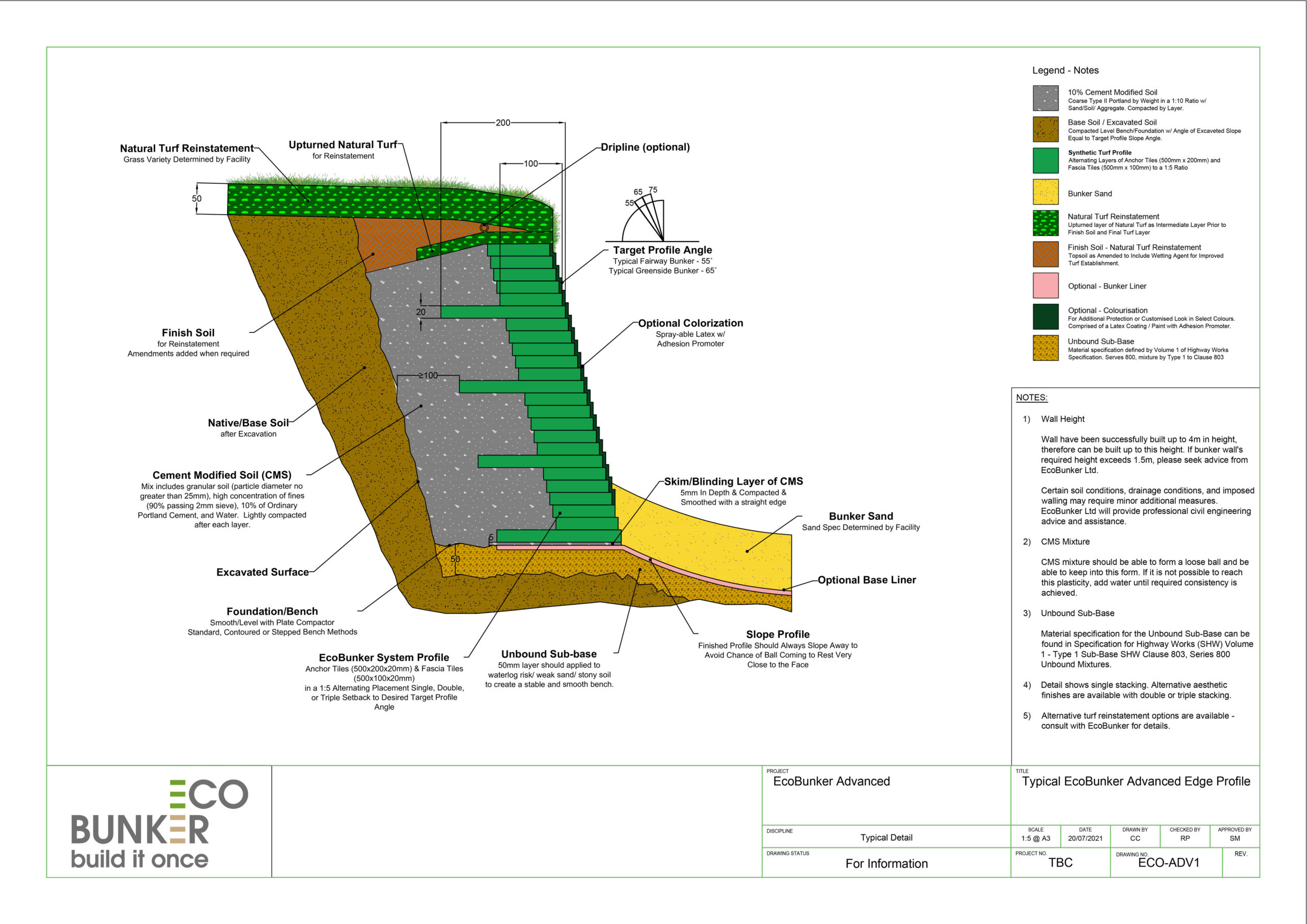

EcoBunker Advanced is not a gravity structure. It performs as a cantilever wall, which is known to all civil engineers as a more efficient method of construction. The diagram below shows a typical cross section through the wall. The tiles come in two sizes, narrower fascia tiles, and wider anchor tiles. The anchor tiles provide a structural link between the fascia and the cement modified soil backfill behind. Unlike the original gravity wall option, structural stability is provided through a combination of the synthetic tiles and the cement modified soil behind.

Key Advantages

Richard, you’ll be pleased to know that our EcoBunkers at Secession have now survived Hurricanes Matthew (2016) and Irma (yesterday)! Many filled with sea water. Skim the silt, add an inch of sand, a little raking and we will be back in business!

It was fascinating to see your new EcoBunker construction comprising revetment of the faces using artificial turf to thwart erosion caused primarily by sheep. You are pioneers in the field. I congratulate you on your initiative as well as the skill of Andrew and his team in implementing the extensive work. They have not only achieved your aim but have improved the appearance of the course dramatically in consequence. From a playing point of view, the bunkers are fair – if to be avoided. They are a lesson to the many courses in the world.

You have an excellent product. I encourage others to take a good look at what it can do for them.

I do feel you have a great product. I’ve been talking with my superintendent about something like this for years now.

EcoBunker is a truly innovative idea. It represents huge cost and labour savings and has solved the particular problems we face on our course which is populated by sheep. This method of construction stands head and shoulders above other bunkers we have built. It not only looks fantastic but performs equally well. We are now in the process of re-constructing all 84 of our bunkers under licence.

It’s my pleasure to recommend Llewellyn Matthews and EcoBunker Ltd. After experiencing Llewellyn’s talent at Trump National, Jupiter and Secession GC, I am confident he will produce the highest quality results in a professional manner. His attention to detail whilst working in harmony with everyone on the project is commendable. I look forward to including Llewellyn and EcoBunker Ltd on future projects.

Richard’s invention is a truly innovative solution that will enable traditional revetted bunkers to be built in areas where previously this has not been an option due to climatic factors.

We’ve had a really positive reaction from both members and visitors. Most of them don’t even realise that the bunkers faces are synthetic….they just get on with their game and enjoy it. I’ve been a member here now for 29 years, and bunkers have always been a problem. But now, with the synthetic faces they are absolutely superb, and it’s all to the benefit pf the golfers who play Southerndown GC.

It was a very big year for Southerndown GC. We hosted the Top Amateur event, The Duncan Putter, hosted Final Qualifying for the Seniors Open at Royal Porthcawl and then welcomed the best golfers in the British Isles for the Home Internationals. Most of the players didn’t realise that the bunker faces were synthetic, and those that did thought they were very good.

St Leon Rot demands high standards, and we were challenged with designing and building a range of resilient bunker styles on the new short game academy. EcoBunker justified their rising reputation in Germany by providing top quality turf, fully professional site support and responsive technical back up.

Contact us about EcoBunker distribution in your territory

EcoBunker Advanced matches the construction speed and the beautiful aesthetics of the original method, but adds in the following benefits:

- 36% increase in structural stability

- 38% decrease in transportation costs

- Improved stiffness, reducing risk of bulging